OCMI OTG S.p.A. & KYP ACCESORIOS SA join forces

Milan, 11th of November 2019

OCMI OTG S.p.A. announces today the successful completion of the acquisition of KYP Accesorios a Spanish company active in the field of automatic production lines for ampoules.

This acquisition marks a significant milestone in both companies’ growth strategy. By joining forces both OCMI OTG and KYP wish to deliver to their customers a wider range of products, a better service and a constant investment in R&D.

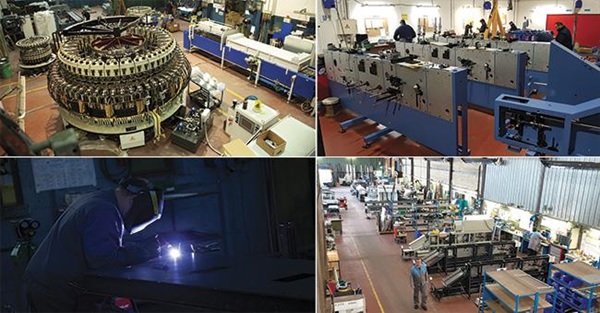

“This acquisition expands OCMI OTG’s portfolio of successful businesses and mark another OCMI investment in the pharma packaging field. KYP is an excellent company with a remarkable story of innovation and dedication to the customers” – Michele Gusti Chairman of OCMI OTG S.p.A, affirmed – “Through this operation OCMI OTG reinforce and consolidate its market share in the ampoule making machines sector, widen its current range of products and increase its production capacity adding a great team strengthens its manufacturing footprint adding more technological capabilities”.

“We are proud to become a part of this international and customer-oriented group like OCMI OTG”

Mr. Raul Paz, KYP Accesorios’s owner commented: “With this deal KYP add another step on its path to continuous growth and innovation and broadens its future horizons. It is a project I strongly believe in, and I am honored to join OCMI Global management Team”

Dear Customer, suppliers, employees, partners

We wish to confirm that all our factories across the world (Milan, Paris, Madrid & Ahmedabad) and our office in Shanghai are fully operational.

We are following all the rules and procedures provided by the local government to guarantee the health and safety of all our employees and their families

Our office staff is equipped to work remotely and is at your disposal for further information.

Estimado cliente, proveedores, empleados, socios

Deseamos confirmar que todas nuestras fábricas en todo el mundo (Milán, París, Madrid y Ahmedabad) y nuestra oficina en Shanghai están en pleno funcionamiento.

Estamos siguiendo todas las reglas y procedimientos provistos por el gobierno local para garantizar la salud y seguridad de todos nuestros empleados y sus familias.

Nuestro personal de oficina está equipado para trabajar de forma remota y está a su disposición para obtener más información.

La Direccion

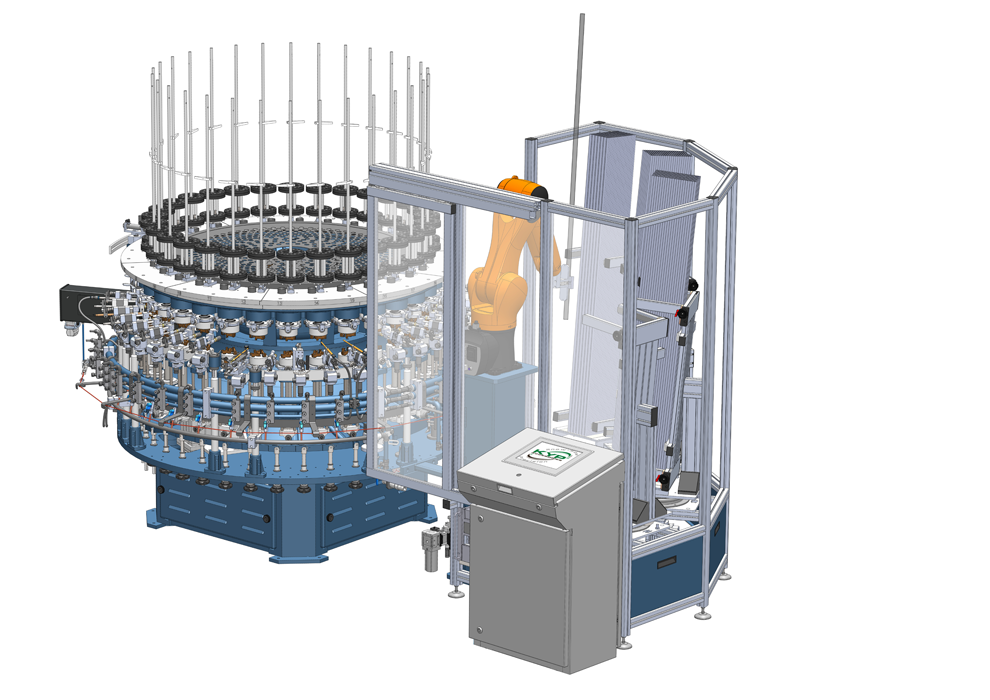

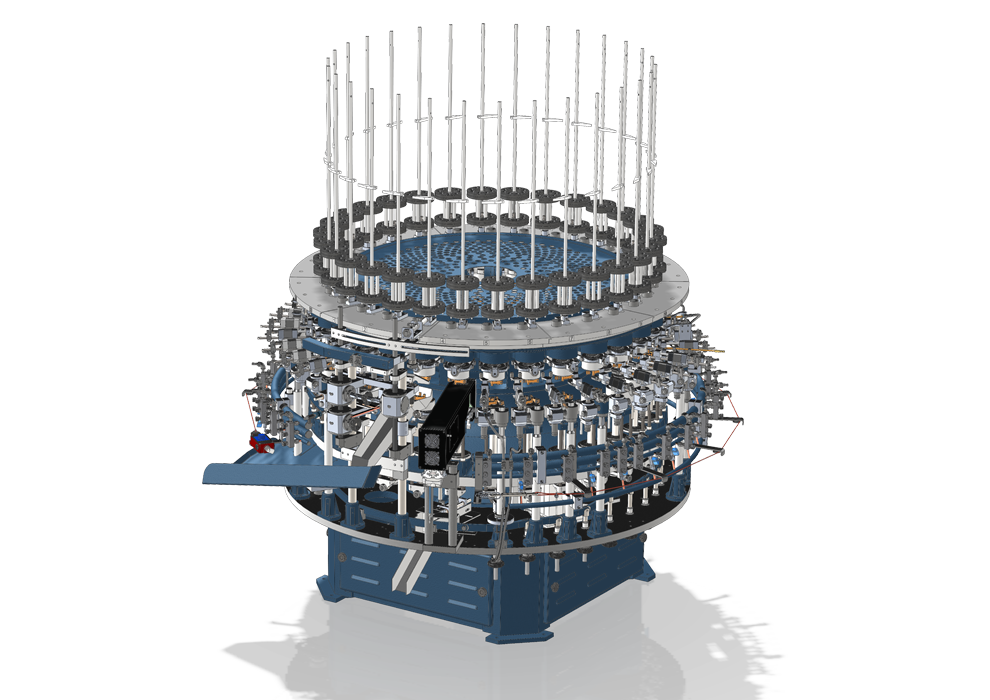

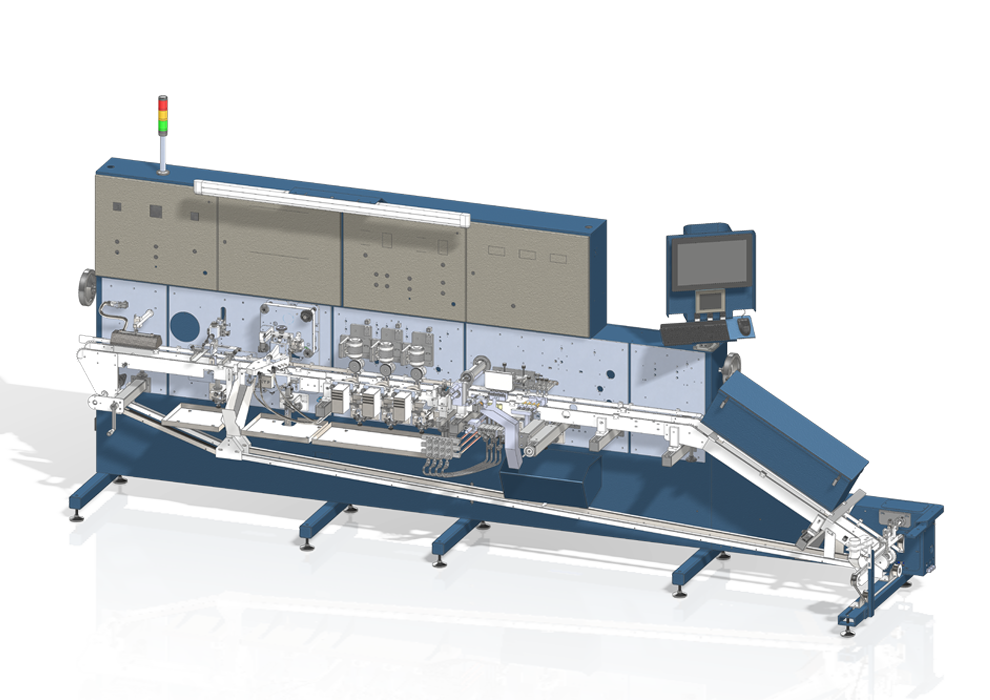

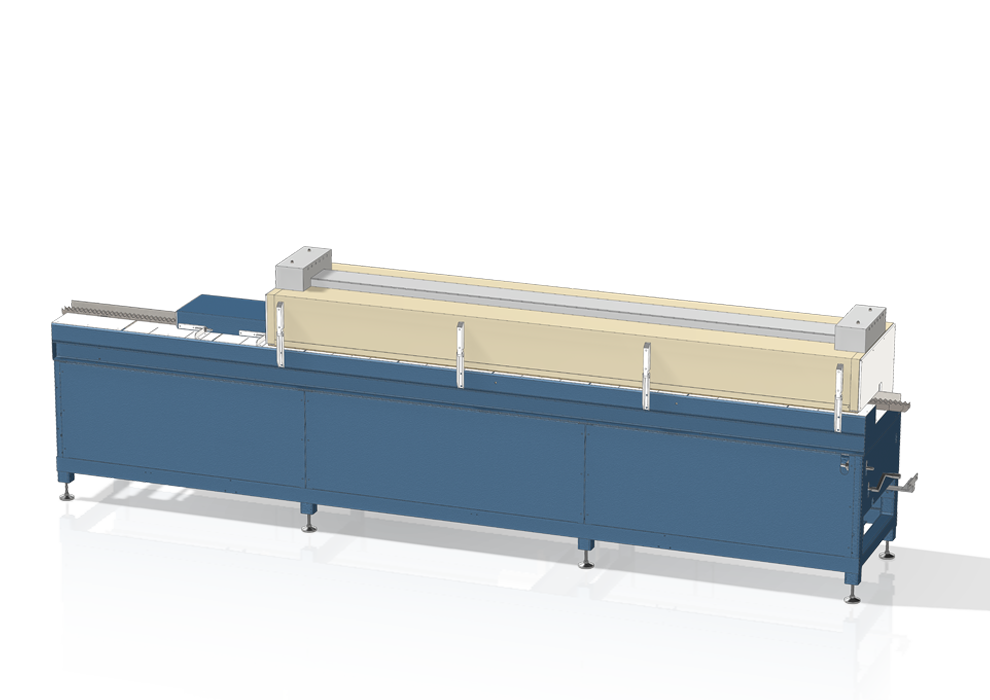

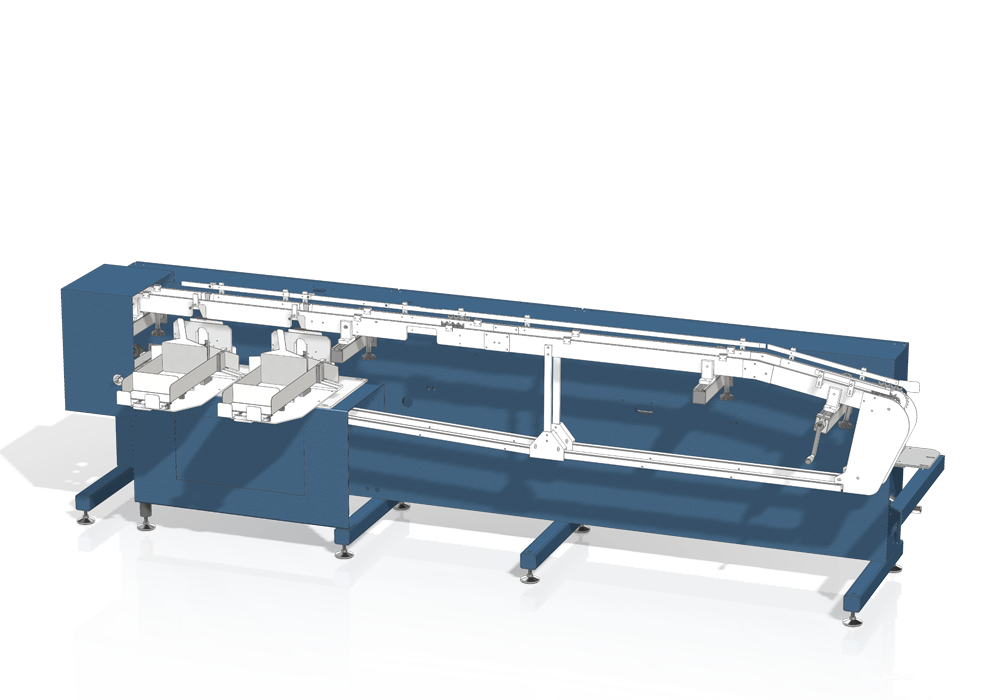

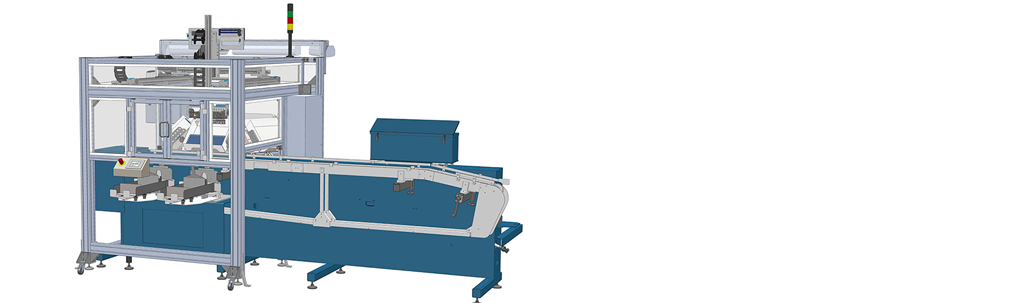

Our products

Additional Options

Distribution in close to 50 countries in the 5 continents

Contact us